Machines for public works & more

CMM offers through its expertise in underground, environment very demanding that requires a simple design of use, maintenance, robust and meets your needs. Also with a clean production tool and having a CMM experienced design office produces equipment that cater to its customers but also underground public works or other areas such as metallurgy, railway industry The LGV etc.

Blast furnace Caroteuse

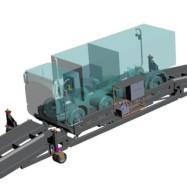

LGV (high speed rail link)

Several turners CMM trucks are used for the realization of LGV high-speed line in order to secure construction sites, increase the stage of completion, facilitate the work of truck drivers and not to damage the freshly laid coating. LGV line Tour-Bordeaux operates by Cosea is also in the process of using turners trucks out of our workshops. They allow the construction to proceed at a steady pace while facilitating and securing all transactions.

CATERING EQUIPMENT

We propose to modify and restore your vehicles for public and underground work, microtunnelling etc … For example we can add a slide drilling or bolting and modify the circuit / hydraulic station accordingly. You can ask us to reconstruct partially or completely mechanically, hydraulically and electrically all your gear and machinery.

CAREER

In view of our extensive experience in underground you can also contact us for your equipment for quarrying or we can for example equip a truck for trade in various hydraulic equipment to make autonomous and thus minimize the number of vehicles and personnel present on the farm.

METAL

CORE BLAST FURNACE

Steelmakers have a permanent need of information on the quality of the melt in blast furnaces.

The most accurate way is sampling a melt is difficult to access

- CMM offers a drilling machine for sampling in blast furnaces in air injection area.

- The machine is designed for:

- Being easy to transport from one site to another compact enough to move on the floor nozzles

- Self-propelled machine electrical energy that can achieve:

The establishment,

Positioning level,

Penetration.

The decline with sampling.

- Drilling to define race as needed

- Average diameter of the probe: 250 to 300 mm.

- The machine is supplied without control equipment and specific measurement (sensors, various sensors … related to the study of blast furnaces.). CMM can provide instructions on settlements with all necessary equipment.

REPAIRS TO THE THRESHOLD DOOR AND DAIRY IN ELECTRIC slagging FOUR

During the merger of various steels, operators manually perform tedious and sometimes dangerous work.

We have adapted our technology to their craft by equipping two of our runners a hammer with an air side and a saddle of another to respectively perform repairs to the furnace door threshold and the slagging of “dairy” in the oven while being mounted on a gantry and the command by remote.

RAIL

All railway equipment operator must monitor the status of bogies and wagon wheels tractor loco.

The oldest and simplest way is to ring each wheel bogie and detect faults in the ear .This requires great experience, knowledge and remains to human appreciation.

For the TGV (high spped train) technical equipment and time savings required during interviews enabled CMM to design a compact machine which can evolve under the oars, lifting bogies, faires turn vibrate to control.

The autonomous device on batteries carries all recorders followed sensors necessary for the proper equipment.

DEMOLITION

From our long experience in drilling and explosive load CMM is able to provide you with drilling equipment microphones door pod, purging, etc., able to squeeze almost everywhere to assist you in your various stages of demolition. These small devices can be electrical and autonomous. They can be controlled by radio or electric control.

- Equipment for drilling

- Demolition NOUVETRA

- Train

- LGV Tours Bordeaux COSEA 2014

- IMPHY Metallurgy

- Modification of Machine

- Blast furnace Caroteuse